Lean Inventory Management

Lean inventory management is one approach a business can use to increase its profitability. It does not replace a good sales team or website presence, rather it aims to increase ROI by implementing improvements to reduce waste.

Waste can manifest in different forms from breakage, to bottlenecks, to malfunctioning equipment. Enacting a plan for lean manufacturing involves analysis, actionable tasks, and reevaluation to measure improvement. With each improvement, the aim is to have no waste and move the company ever closer to that goal.

Planning Your Lean Inventory Management Strategy

Some sources of waste may be commonly discussed in company meetings; others may come to light once the strategy is discussed. The easiest way to get started is to make a list and then begin working on the low hanging fruit. A few ideas include:

- Analyze product performance using reports. SOS Inventory makes it easy to take deep dives into any product’s history with customizable parameters. Reports often reveal sources of waste.

- Speak with floor managers at each workstation to understand where things go wrong or hear suggestions for improve workflow.

- Adjust reorder points to match demand to reduce overages.

- Implement software, like SOS Inventory, that integrates all work processes from different areas of the business into a single, central platform where everyone has access to identical information.

While the goal is to reduce waste, the lean inventory strategy to get there must stay within limits to preserve the quality of your product. Increasing profitability shouldn’t come at the cost of disappointing customers creating loss at the other side of the business.

Your lean manufacturing practices should continually move you to your goal of eliminating all waste. You might choose to focus on specific areas first, such as lean warehouse management, with the aim to broaden the efforts over time. Even if zero waste seems impossible, the journey to get there will increase profitability.

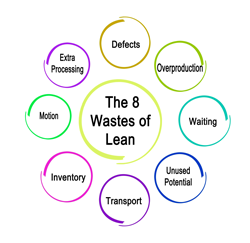

The most common sources of waste that lean manufacturing principles can solve include:

Overproduction: Excess production can lead to excess inventory, increased lead times, and higher costs. By implementing a pull system that produces only what is needed when it is needed, businesses can alleviate this problem.

Waiting: When there is a delay in the manufacturing process due to a lack of materials, information, or equipment, lead times go up, productivity goes down – and sometimes it stops completely. A just-in-time system, one that ensures materials, information, and equipment are available when needed, is often a good solution.

Transportation: When materials, products, or equipment are moved unnecessarily during the manufacturing process, costs go up, lead times get longer and there’s a greater risk of damage to products. The key is to devise a plan to minimize the distance and frequency of material movement.

Processing: When processes are overly complex or unnecessary, you have the same problem with costs and lead times. Simplifying process to entail fewer steps and improve workflows can alleviate this problem.

Inventory: When when excess materials, products, or supplies are held in inventory, costs go up, cash flow gets tight and there is a tendency for obsolescence. Here again, a just-in-time system is an option.

Defects: When products fail to meet customer requirements, the most likely outcome is profit loss, an unhappy customers, and bad reviews which erode the business’ reputation and potential for business growth. Implementing quality control measures should reduce the potential for returns due to product quality.

Considerations: Lean Inventory Practices

Can you cut costs by changing your supplier and still maintain that quality? That’s one question to consider, yet if savings comes at the price of poor communication or inconsistencies in quality, then you are defeating the purpose. Finding a new supplier takes time and research and you can make a more informed decision if you look into it when things are running normally – not because you have no other choice.

Can you cut costs by changing your supplier and still maintain that quality? That’s one question to consider, yet if savings comes at the price of poor communication or inconsistencies in quality, then you are defeating the purpose. Finding a new supplier takes time and research and you can make a more informed decision if you look into it when things are running normally – not because you have no other choice.

Lean inventory management is essentially the continuous tweak, tweak, tweak to make small, sustainable improvements. Waste can occur anywhere in the business, even in administrative tasks. Lean management won’t look the same for every business; there will be some lean inventory management techniques that are more successful in your industry than others.

Take a look at the flow of inventory. It can be slowed anywhere along the chain from the supplier, various stages of production, or fulfillment. Increasing the speed of this flow should add value to your business – as long as it doesn’t come at the cost of  delivering quality to your customers. Improving speed could mean rearranging workstations on the floor to optimize workflow or upgrading equipment.

delivering quality to your customers. Improving speed could mean rearranging workstations on the floor to optimize workflow or upgrading equipment.

The lean inventory management model works well for just in time inventory businesses since they operate with minimum inventory on hand, ordering only when they must fill a sale. Rather than relying on historical sales data, the approach here is reacting to demand in real-time. Using a perpetual inventory system can assist in providing the most up to date inventory numbers across the business.

SOS Inventory provides businesses all the tools they need for lean inventory management and lean order management from the ability to use a perpetual inventory system, track every sale, cost and action across from one end of the business to the other and offer in-depth analysis of any product from any angle you want to assess. Tap into the potential of lean manufacturing software benefits with a subscription to SOS Inventory. Add more value to your business and turn a higher profit. Get started with a free trial today.